Green Lubes Malaysia Sdn Bhd is in the business of Bio-fuels and is currently working on refurbishment of its newly acquired, as-built integrated bio-diesel production facility at Kuantan, Malaysia. The Facility was previously known as FGV Mission2 plant. GLM has plans to re-commission & start the commercial production.This facility has production capacity of 250,000 tons per annum Bio-diesel with 260,000 tons per annum Oil Pre-treatment plant to convert CPO to RBD.Also this facility is integrated with a Vacuum Distillation Plant with production capacity of 250,000 tons per annum with all utilities support.

This facility is integrated with storage tanks with more than 24,000 tons of raw materials, finished products storage . Additional storage tanks of 20,000 tons capacity will be constructed for blending operation and multiple feed storage purposes. This plant is strategically located near the Kuantan port and equipped with 2nos dedicated pipeline facility for direct export of products to overseas markets. The Key Management personnel have vast experience of more than 30 years in the Petroleum & Bio-diesel Industry working for the National and Global Oil & Gas companies.

Our state-of-the-art 260,000 TPA Oil Pre-Treatment Plant is a cornerstone of our biodiesel production process, ensuring the highest quality feedstock for our advanced operations. This facility plays a vital role in the oil industry by effectively removing contaminants such as phospholipids, free fatty acids, pigments, and other impurities. =>Key Features and Processes:- 1)With a significant capacity of 260,000 tons per annum, our plant efficiently handles large volumes of raw materials, including animal fats, used cooking oils, and vegetable oils such as canola, soybean, and palm.2)High-Quality Feedstock: The output from our pre-treatment plant not only supports our biodiesel production but also serves as essential input for Sustainable Aviation Fuel (SAF) production, driving innovation and sustainability in the aviation industry. 3) Enhanced Efficiency: By improving the efficacy and efficiency of downstream refining processes, our Oil Pre-Treatment Plant significantly enhances the yields of refined oil products. *Our commitment to quality and sustainability positions us at the forefront of the biodiesel and aviation fuel industries, ensuring cleaner and more efficient energy solutions for the future.

Our cutting-edge 2,250,000 TPA Biodiesel Plant stands as a testament to our commitment to sustainable energy production. Utilizing the finest feedstock from our Oil Pre-Treatment Plant, we process animal fats, used cooking oils, and vegetable oils (including canola, soybean, and palm). The primary procedure is transesterification, where feedstock triglycerides react with methanol in the presence of a catalyst, yielding high-quality biodiesel and glycerin. Additionally, our facility produces feed for Sustainable Aviation Fuel (SAF) plants, supporting cleaner energy solutions for the aviation industry. With advanced production techniques and rigorous quality control, our plant ensures efficient, reliable, and eco-friendly fuel output. This plant not only underscores our leadership in the clean fuel industry but also drives us closer to our vision of becoming the No.1 biodiesel producer in Asia, contributing to a greener, more sustainable future.

Our state-of-the-art 250,000 TPA Vacuum Distillation Plant is integral to our biodiesel production process, ensuring the highest quality and purity of our final products. This facility utilizes advanced vacuum distillation techniques to refine and purify the feedstock, including animal fats, used cooking oils, and vegetable oils (such as canola, soybean, and palm). By operating under reduced pressure, the vacuum distillation process effectively separates contaminants and enhances the quality of our biodiesel and the feed for Sustainable Aviation Fuel (SAF) plants. This ensures that our end products meet stringent environmental and industry standards. Our Vacuum Distillation Plant underscores our commitment to excellence and sustainability, reinforcing our position as a leader in the clean fuel industry and driving us towards our goal of becoming the No.1 biodiesel producer in Asia.

Our tank farm has a capacity of 22,500 MT. The tank farm plays a vital role in our biodiesel production process by providing reliable and secure storage solutions that support continuous and efficient operations. By ensuring that raw materials and finished products are stored under optimal conditions, we maintain the high quality of our biodiesel and SAF feedstock, which is essential for meeting stringent industry standards and achieving our sustainability goals.

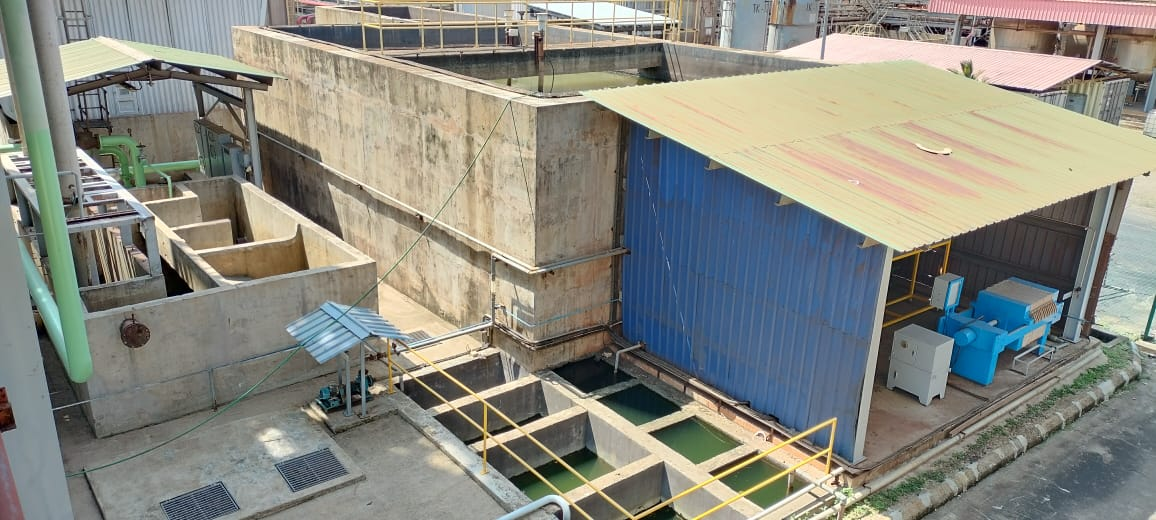

The utilities infrastructure is the backbone of our production facility, providing essential services that support all aspects of our operations. By ensuring a reliable and efficient supply of power, water, steam, and other utilities, we can maintain high standards of production, safety, and environmental responsibility.Electricity: Ensures continuous operation of all machinery and equipment.

Provide reliable power during outages, ensuring uninterrupted production and safety.

Process Water: Essential for various stages of oil pre-treatment and biodiesel production, including cleaning, cooling, and steam generation. Firefighting Water: Dedicated supply for fire suppression systems, ensuring safety and regulatory compliance.

Used in heat exchangers and cooling towers to maintain optimal temperatures in various processes.

Steam boilers are crucial in apartment construction for providing efficient heating and hot water. Their reliability and performance directly impact residents' comfort and energy costs.

Provide compressed air for pneumatic control systems, instrumentation, Jetty pipelines Pigging and other operational needs.

crucial in apartment construction for treating wastewater generated from various activities, ensuring compliance with environmental regulations

crucial for monitoring and managing complex industrial processes, offering real-time data acquisition, analysis and ensure operational reliability.

crucial for protecting residents and property, encompassing measures such as fire suppression, emergency lighting, and secure entry points

The Production plant is located in Kuantan port, Pahang, Malaysia in 5.9 Acres of Land equipped with dedicated pipelines to the jetty adjacent to import the Feed / raw materials and export the finished products. The Biodiesel Production was originally designed to produce 100% Biodiesel (Palm Methy Esters) from Crude Palm Oil Feed.

The Production plant is located in Kuantan port, Pahang, Malaysia.The Biodiesel Production facilities has provisions to upgrade the existing the Pre- treatment with appropriate technology and additional processing options to process the UCO and POME oils to improve the flexibility of the facilities to produce to low cost Biodiesel Feed / Sustained Aviation Fuel Feed from the facilities.